In every industry, be it manufacturing, healthcare, logistics, or technology, equipment and assets play a critical role in delivering safe, reliable, and high-quality outcomes. Facilities Management (FM) is the backbone that supports these industries. It enables smooth day-to-day functioning of facilities while driving efficiency, employee well-being, and organizational productivity.

FM teams handle a wide range of responsibilities: optimizing costs associated with operations and maintenance of utilities, managing workplace optimization including space utilization, coordinating with local authorities to ensure workplace compliance, and overseeing vendor management. In many ways, Facilities Management functions as an industry of its own – managing people, assets, vendors, and key business processes. Ultimately, FM ensures that all physical assets, infrastructure, and support services are efficiently managed to provide a safe, reliable, and productive environment.

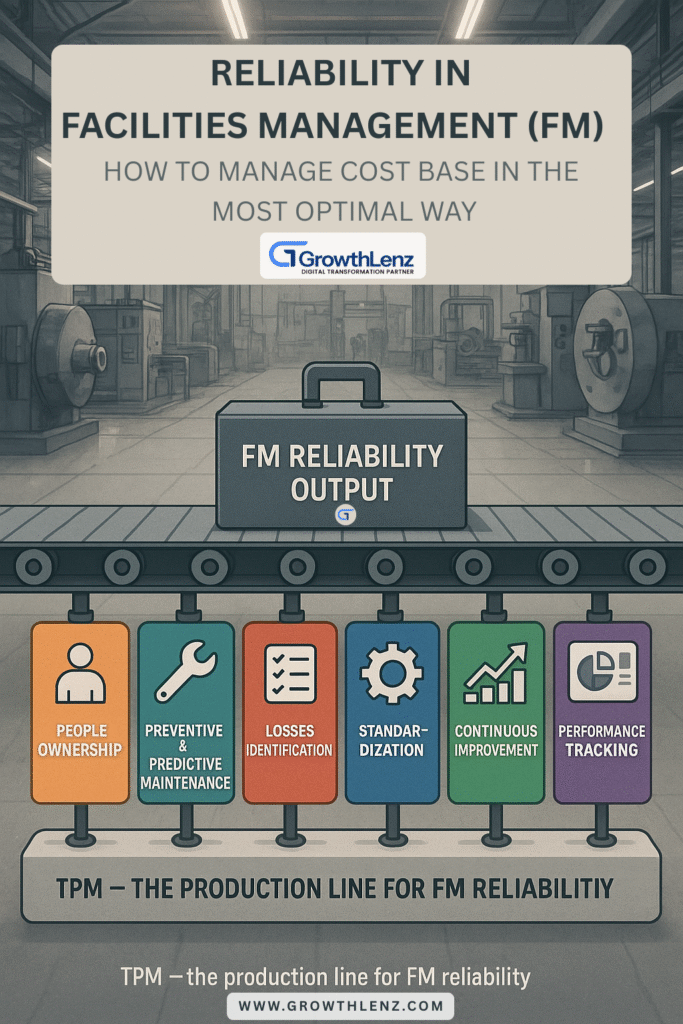

To optimize costs while ensuring reliability, FM teams must embed a strong maintenance strategy reinforced by Total Productive Maintenance (TPM). TPM goes beyond routine upkeep by focusing on reliability, ownership, and continuous improvement.

What Should Be Done to Infuse Total Productive Maintenance in Facilities Management?

- People Ownership Across Levels

- Train frontline staff (technicians, operators, housekeeping, and security) to take responsibility for the basic care of equipment and assets.

- Encourage “first-level maintenance” (often called operator maintenance), such as cleaning, inspection, lubrication, and tightening – daily checks that prevent small issues from becoming bigger failures.

- Preventive & Predictive Maintenance

- Shift from reactive repairs to planned maintenance schedules. Auto-scheduling of periodic maintenance is now considered best practice across FM teams.

- Leverage condition-monitoring tools (IoT sensors, thermal scanning, vibration analysis) to predict failures before they occur.

- Maintain detailed service logs for all critical systems. Digitized records act as a standardized repository for knowledge and support future improvements.

- Eliminate the Six Big Losses

TPM focuses on reducing six common sources of inefficiency:

- Yield losses

- Equipment breakdowns

- Setup and adjustment delays

- Reduced operating speed

- Idle time

- Defects and rework

FM teams should map these losses to facility operations, such as chiller downtime, lift breakdowns, or energy wastage, to identify high-impact areas for improvement.

- Standardize Processes & Documentation

- Develop SOPs (often provided by equipment suppliers at the time of installation) for recurring maintenance tasks.

- Implement 5S practices (Sort, Set , Shine, Standardize & Sustain) in utility rooms, workshops, and storage areas.

- Use digital CMMS (Computerized Maintenance Management Systems) platforms for scheduling, tracking, and advanced analytics.

- Continuous Training & Skill Development

- Train staff in TPM concepts, root cause analysis, and structured problem-solving. This should be a starting point for building a strong maintenance culture.

- Map staff skills against maintenance tasks so that scheduling aligns the right expertise with the right job.

- Measure Performance & Track Improvement

- Track key metrics such as Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), Overall Equipment Effectiveness (OEE), energy efficiency, and service uptime.

- Apply Kaizen (continuous improvement) methods to eliminate recurring issues and gradually raise the standard of reliability.

From Reactive Caretakers to Strategic Enablers

By integrating TPM, FM teams move from being reactive caretakers to strategic enablers of asset reliability, energy efficiency, and workplace productivity. Instead of acting like emergency doctors who rush in when the building “falls sick,” FM teams become health coaches who keep facilities in peak condition through regular care and early detection. Just as preventive health checkups reduce costly hospital visits, TPM ensures assets run reliably, energy is used efficiently, and employees experience seamless comfort. In this way, facilities management becomes a strategic enabler, not just a cost center.

Real-World Incidents Highlighting the Cost of Reactive Maintenance

- Chiller Breakdown in a Commercial Office Complex

Skipping periodic maintenance led to scale buildup in chiller tubes. The failure occurred during peak summer, resulting in costly downtime and repair expenses approx. 4-5 times higher than routine maintenance.

- UPS Battery Failure Leading to Power Outage

Postponing routine battery load testing causes UPS failure during a power outage. This could lead to server crashes and business systems going offline. The indirect financial impact is significant.

Conclusion

Reliability in facilities management is not just about fixing issues quickly; it is about preventing them altogether. By embedding TPM principles, FM teams can manage their cost base in the most optimal way while ensuring business continuity, energy efficiency, and employee satisfaction. A proactive, structured approach to maintenance transforms facilities from cost liabilities into strategic assets that deliver consistent value.

Book an Appointment: https://outlook.office365.com/book/GrowthLenz@growthlenz.com/