Introduction

In pharmaceutical manufacturing, every asset—from reactors and cleanroom utilities to packaging lines is mission-critical. Each piece of equipment directly impacts product quality, regulatory compliance, and operational efficiency.

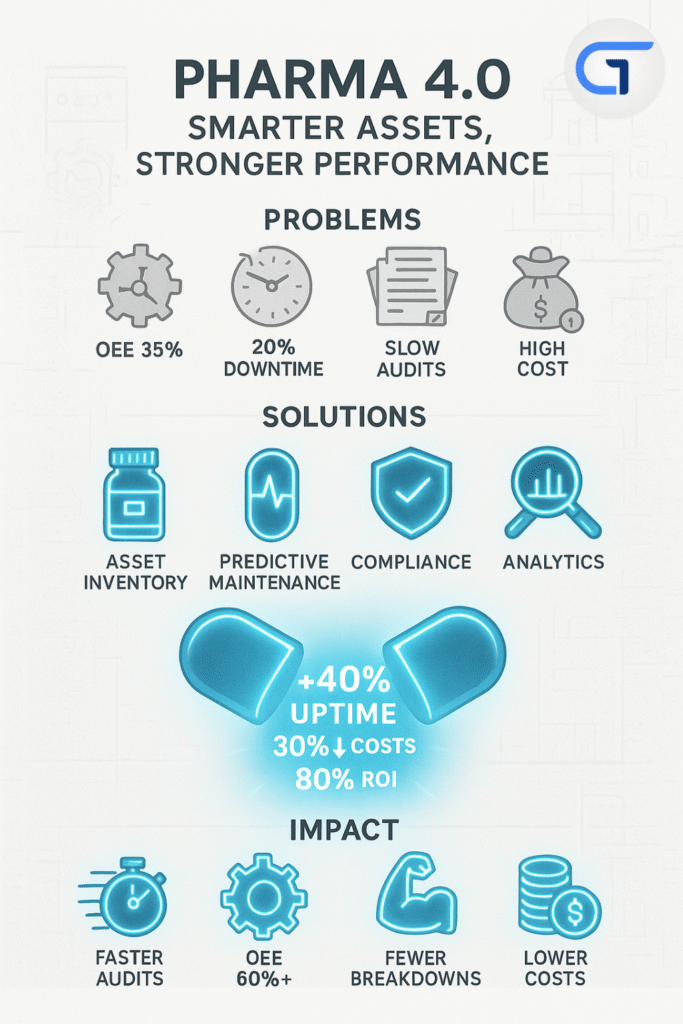

Despite this, many pharma organizations still rely on fragmented records, paper-based maintenance schedules, and reactive interventions. This leads to unplanned downtime, increased maintenance costs, and potential audit risks, which ultimately affect production throughput and profitability.

To understand the potential for improvement, it helps to look at industry benchmarks. These figures highlight where digital asset life cycle management can deliver the most measurable impact.

Industry Benchmarks That Matter

- OEE in Pharma: Average overall equipment effectiveness (OEE) in traditional pharma facilities hovers around 35–37%, while digital-first operations can push OEE toward 60%+.

- Downtime Impact: In conventional setups, 20% of staffed time is often lost to unplanned downtime. Digitally managed environments reduce this to ~11%.

- Predictive Maintenance ROI: Predictive maintenance reduces maintenance costs by up to 30%, boosts equipment uptime by 27–40%, and achieves a positive ROI in over 80% of implementations.

- Audit & Compliance Efficiency: Digital record-keeping can cut documentation errors by more than 50%, and reduce batch reconciliation from hours to minutes, ensuring readiness for regulatory inspections.

GrowthLenz Digital Advantage

GrowthLenz enables pharma manufacturers to achieve and exceed these benchmarks through a robust digital platform:

- 360° Asset Inventorisation

- Every piece of equipment digitally tagged and centralized.

- Single source of truth across facilities for quick access.

- Smart Maintenance Management

- Predictive alerts minimize unplanned failures.

- Scheduled workflows ensure GMP and regulatory compliance.

- Compliance-Ready Documentation

- Automatic logs of calibration, validation, and service history.

- Always audit-ready, eliminating last-minute scrambling.

- Performance Analytics & Insights

- Asset-level cost, downtime, and utilization visibility.

- Data-backed decisions for repair, replacement, or upgrade.

Measurable Impact

- 30–40% fewer unplanned breakdowns with predictive maintenance.

- 10–15% lower life cycle costs through optimized utilization.

- Faster, stress-free audits with automated compliance records.

- Higher OEE, reaching the 60%+ benchmark with consistent uptime, better performance, and stronger quality.

Conclusion

In pharmaceutical manufacturing, every asset is mission critical. Managing asset life cycles digitally isn’t just about reducing downtime; it’s about ensuring compliance, safeguarding product quality, and protecting profitability.

With GrowthLenz, pharma manufacturers move from reactive firefighting to proactive, data-driven performance—turning assets into enablers of growth and operational resilience.