Stop Losing Tribal Knowledge — Turn It into Actionable Insight

Capture operational know-how, audit observations and field knowledge the moment they happen and convert them into structured, reusable knowledge that improves asset uptime, safety and productivity.

- Capture tacit knowledge directly from operators, technicians and auditors

- Convert unstructured field notes into structured digital knowledge

- Auto-tag and map information to assets, parts and workflows

- Surface insights where they matter – maintenance, reliability, field service, training

Operations break when knowledge stays in people’s heads

Common issues

- Critical knowledge lost during shift changes and staff turnover

- Audit observations captured manually and never reused

- Failure patterns and corrective actions not recorded consistently

- Training and onboarding rely on a few experts, not structured content

- OEMs unable to analyse field reports across customer sites

Outcomes with GrowthLenz Knowledge Intelligence

- Knowledge captured once and reused across teams and sites

- Corrective actions and failure history available during decisions

- Faster onboarding and fewer repeat mistakes

- Standardisation across plants, suppliers and field teams

- Lower service cost and higher first-time fix rates

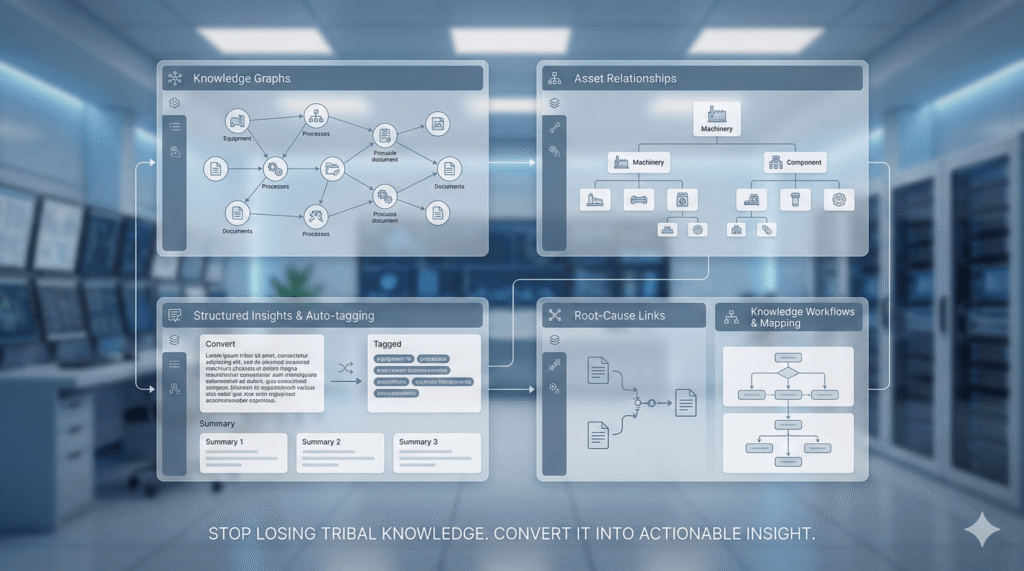

The fastest way to convert tacit knowledge into structured knowledge

Capture, organise and surface operational knowledge so it supports decisions in maintenance, reliability, field service and training.

Data Capture Agent

Record audits, inspections and operator insights via mobile or web – including in low-connectivity environments.

Unstructured-to-Structured Conversion

Convert free text, checklists and documents into organised digital knowledge mapped to assets, parts and issues.

Knowledge Workflows

Trigger corrective and preventive workflows automatically based on captured observations, root causes and risk.

AI-Driven Knowledge Retrieval

Ask questions in natural language and get answers sourced from real machine, maintenance and field history.

Built for the places where decisions are made

Knowledge flows across plant operations, maintenance, and OEM field service teams to support better, faster decisions.

Plant Operations

- Capture shift learnings and corrective actions

- Prevent repeated failure patterns between shifts

- Provide operators with quick access to past fixes

Maintenance & Reliability

- Access root causes, past interventions and OEM insights

- Support PdM, RCA and continuous improvement with evidence

- Link knowledge directly to assets, systems and components

OEM & Field Service

- Learn from every breakdown and site visit

- Share proven fixes across customer sites

- Improve warranty management and parts planning

See the Knowledge Intelligence Platform in action

Dashboards and views designed for operations, maintenance, quality, training and service teams.

- Audit-to-action workflow tracking with full closure visibility

- Auto-classification of findings by asset, category and risk level

- Intelligent search by symptom, component or corrective action

- Failure trend analytics to drive preventive planning

- Insights pushed into CMMS, ERP, LXP and field service tools

Dashboard screen 1

Dashboard screen 1

Dashboard screen 1

Measured impact from Knowledge Intelligence

40%

60%

35%

30%

Frequently Asked Questions

What types of knowledge can be captured?

How is this different from a traditional document management system?

Traditional systems store documents. Knowledge Intelligence structures information around assets, issues and actions, then makes it searchable and operational – so it supports maintenance, reliability and service decisions.

Can technicians use it even with limited typing skills?

Yes. Forms are simple and guided, and data can be captured via checklists, dropdowns, photos and short notes, then enriched automatically in the background.

How does it link with ERP, CMMS, LXP and field service tools?

Knowledge objects can be linked to work orders, training modules, assets and service tickets, and we provide integration options to common ERP, CMMS, LXP and service platforms.

What is the typical rollout timeline?

A focused pilot can go live within weeks. We start with a priority use case, then extend to other teams and sites once the model and workflows are tuned.

Ready to unlock the knowledge trapped inside your operations?

Share a few details and we’ll show how Knowledge Intelligence can reduce repeat failures, improve training time and scale expert decision-making across teams.

- No obligation demo

- Tailored to your industry

- Clear ROI roadmap in the first call