How GembaFix™ is Redefining Frontline Excellence for the Next Industrial Revolution

Industry 5.0 marks a crucial evolution in industrial manufacturing and operations, shifting beyond the automation-centric focus of Industry 4.0. This new paradigm prioritizes a balanced, human-centric, sustainable, and resilient approach where cutting-edge technologies; AI, IoT, robotics; work symbiotically with human creativity, intuition, and decision-making.

The Human-Centric Revolution

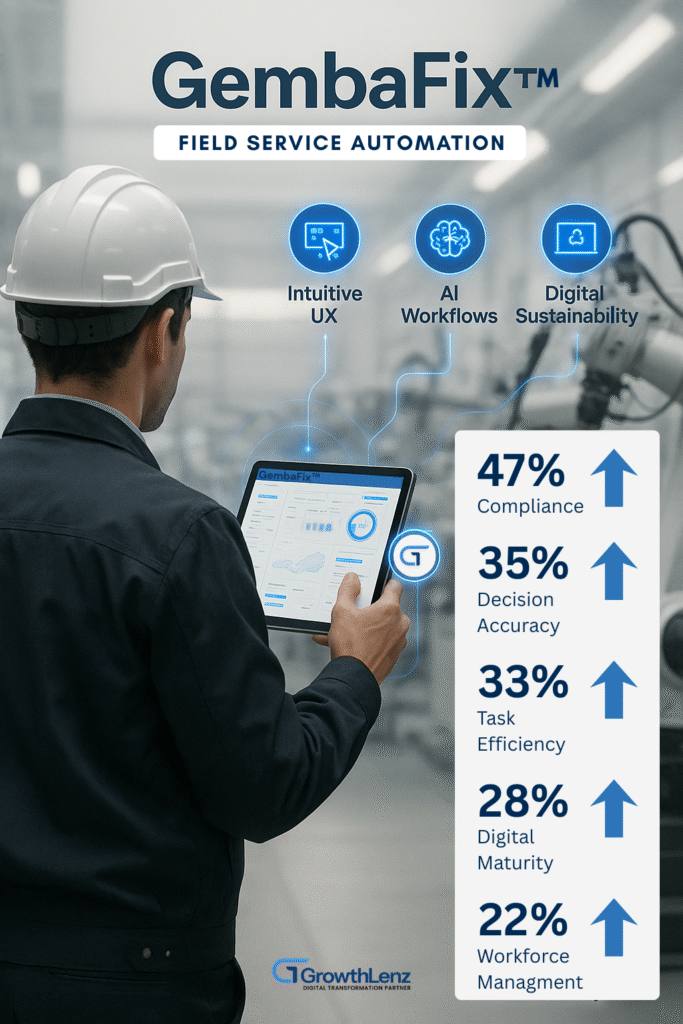

Unlike previous industrial revolutions that prioritized mechanization and automation, Industry 5.0 positions humans back at the center of operational success. Recent benchmarks reveal organizations that engage human-machine collaboration achieve up to a 35% increase in decision accuracy versus fully automated systems. This synergy fosters 28% higher digital maturity and a 22% increase in workforce engagement, underlining how technology can empower rather than replace skilled workers.

GembaFix™: Empowering Real-Time Workflows

At the core of Industry 5.0’s promise lies the concept of Gemba; the frontline where value is created. Traditional paper checklists fall short when facing today’s complexity. GembaFix™ transforms this experience by delivering intelligent, adaptive digital checklists designed to boost efficiency and accuracy, reduce cognitive load, and embed sustainability directly into daily workflows.

GembaFix™ features:

-

Intuitive UX enhancing adoption across workforce levels

-

AI-driven smart workflows adapting dynamically to real-time operational data

-

Digitally enabled sustainability, reducing paper and waste

-

Predictive analytics enabling continuous operational improvement

Empirical data highlights up to a 47% improvement in compliance accuracy, a 33% increase in task completion efficiency, and an 18% boost in sustainability outcomes through digital checklist adoption.

Industry 5.0 Market and Performance Benchmarks

The Industry 5.0 market is expanding rapidly with forecasts estimating growth from USD 93 billion in 2025 to nearly USD 1 trillion by 2034, driven by increasing adoption of collaborative robotics and digital intelligence solutions.

Across sectors, key performance improvements include:

-

40% greater operational agility and 25% less unplanned downtime due to interconnected, adaptive systems

-

30% reductions in errors from enhanced human-machine partnerships

-

15% improvements in resource efficiency supporting circular economy models and environmental goals

Digital twins, predictive maintenance, and smart supply chains are among the technologies underpinning these outcomes.

GrowthLenz: Championing the Future of Industry 5.0

GrowthLenz is driving this transformation with its commitment to solutions like GembaFix™, creating tools that bridge human expertise and digital intelligence. As companies navigate the transition, this new industrial revolution demands technologies that empower people, foster sustainability, and build operational resilience.Industry 5.0 is not about replacing humans with robots; it is about enabling humans with smarter tools, catalyzing a new era of innovation, responsibility, and productivity.

Are you ready to lead your organization into Industry 5.0? Discover how GembaFix™ can transform your operational excellence and empower your workforce for a resilient, sustainable future. Contact GrowthLenz today to learn more.

#Industry5 #HumanCentricAI #DigitalTransformation #SmartManufacturing #Sustainability #AI #IoT #OperationalExcellence #GembaFix #FutureOfWork #Innovation #Resilience #GrowthLenz