Asset Lifecycle Intelligence for Higher Uptime and Lower Warranty Cost

Real-time visibility, predictive maintenance and proactive parts planning for manufacturers and OEMs.

- Cut unplanned downtime and improve OEE

- Predict failures and plan interventions earlier

- Reduce warranty leakage and service cost

- Optimise spare parts and supplier performance

Why Asset Lifecycle Management Fails Without the Right System

Common challenges

- Data scattered across systems and spreadsheets

- No clear view of asset condition and run hours

- Maintenance based on time, not actual usage

- Poor visibility of warranty exposure

- Reactive spare-part ordering and stock-outs

Outcomes with GrowthLenz

- Uptime gains and stable OEE

- Predictive triggers based on performance signals

- Planned maintenance windows instead of surprises

- Warranty risk visible by asset, site and supplier

- Better spares planning and supplier evaluation

Everything Needed to Control the Asset Lifecycle

Focused capabilities that link asset data, performance signals, warranty exposure and aftermarket opportunities into one view.

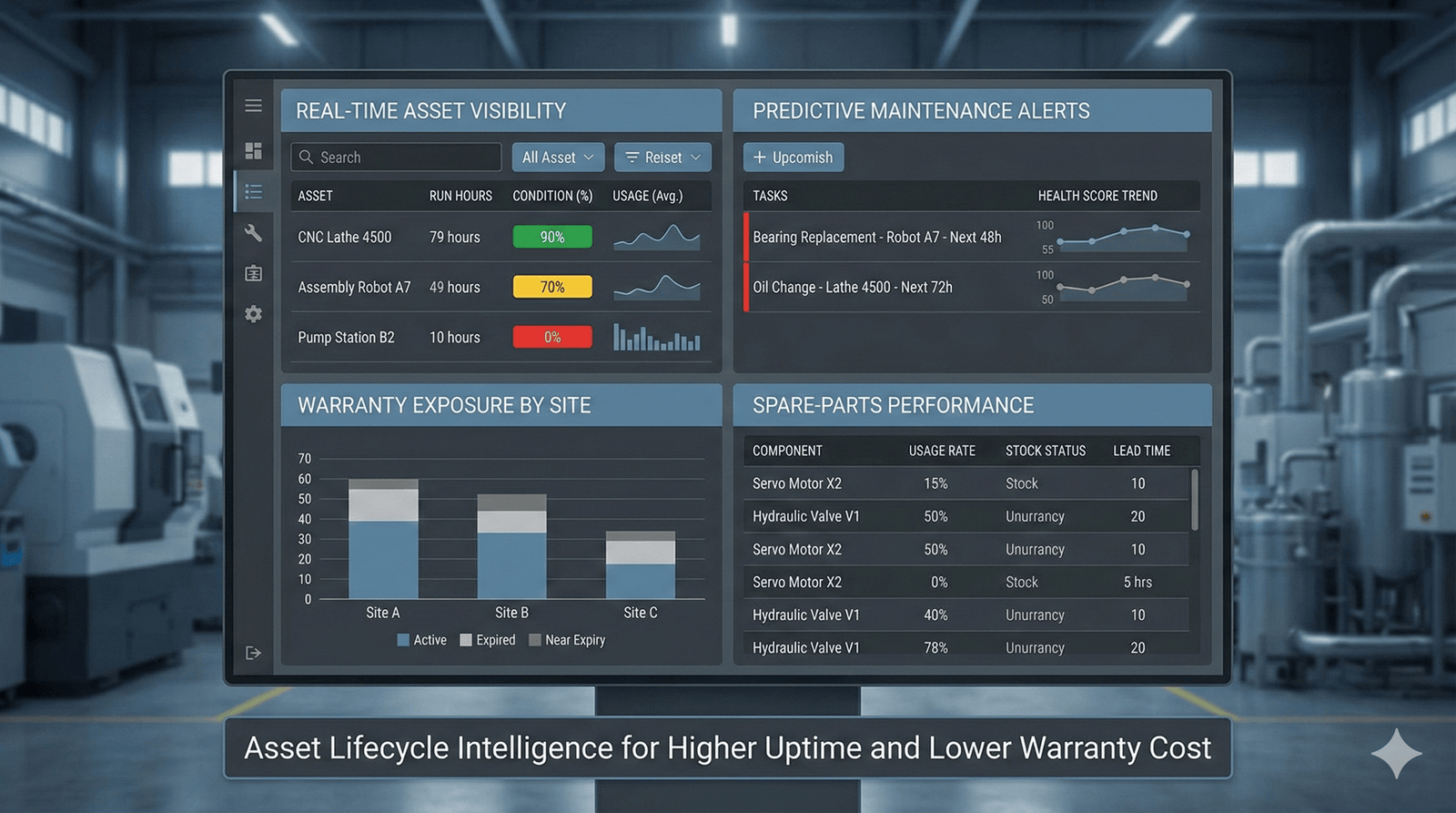

Real-Time Asset Visibility

Track run hours, condition and usage across sites, mapped to flowsheets and process units.

Predictive Maintenance & Alerts

Use performance-based triggers and risk scoring for earlier inspections and repairs.

Warranty & Lifecycle Cost Management

Capture warranty terms and claims by asset to identify leakage and recurring failure patterns.

Parts, Suppliers & Aftermarket

Manage parts catalogues, substitutes and wear parts with supplier scorecards on cost, quality and delivery.

From Data to Decisions in Three Steps

STEP 1

Discover

Import asset, product and site data. Define hierarchies, sub-assemblies and parts across plants.

STEP 2

Design

Configure thresholds, maintenance strategies and triggers with views for operations, maintenance and sales.

STEP 3

Deploy

Roll out dashboards, alerts and workflows, monitor KPIs and scale across plants and regions.

Designed for Both Manufacturers and OEMs

For Manufacturers

- Improve uptime and OEE on critical lines

- Predict failures across kilns, mills, crushers, compressors and more

- Align maintenance plans with production schedules

- Avoid emergency breakdowns and high-cost interventions

For OEMs

- See installed base performance by customer, site and model

- Identify high-risk assets before they fail in the field

- Reduce warranty cost with earlier intervention

- Build proactive aftermarket service and parts revenue

See the Platform in Action

Dashboards and views built for operations, maintenance, reliability and commercial teams.

- Structured asset and product ontology for assets, sub-assets and parts

- Customer and site mapping linked to process units and flowsheets

- Run-hour and usage tracking to understand utilisation patterns

- Aftermarket potential and coverage views to support service and parts teams

Dashboard screen 1

Dashboard screen 1

Dashboard screen 1

Measured Impact from Asset Lifecycle Intelligence

+X%

+X%

+X%

+X%

Frequently Asked Questions

What are the stages of Asset Lifecycle Management?

Typical stages include planning, acquisition, commissioning, operation, maintenance, renewal and disposal. Our platform helps you monitor and control each stage with data-driven insights.

How is this different from a standard CMMS or ERP module?

CMMS and ERP systems record work orders and costs. Asset Lifecycle Intelligence focuses on performance signals, risk, warranty exposure and aftermarket opportunities on top of those systems.

Can this run on-premise?

Yes. Deployments can be on-premise or hybrid to meet your security, compliance and connectivity requirements.

What integrations are supported?

How long does implementation typically take?

Ready to Take Control of Asset Performance?

Share a few details and we’ll show you what Asset Lifecycle Intelligence would look like for your assets.

- No obligation or long presentations

- Walkthrough based on your industry

- Clear next steps and indicative ROI